Qbig Packaging

Liner solutions

At Qbig, you have a choice among various, some self-designed and patented, liners.

Below you can see a small overview of several liners we can produce for you

Our liners

At Qbig, you have a choice among various, some self-designed and patented, liners. Tailored for different applications, with patented folding patterns and shapes to cater to a wide range of containers, ranging from 250 to 1400 liters. In addition to the standard pillow liner, we also offer the T-liner and Free Flow Gusset (FFG) liner we developed ourselves. These high-quality liners provide extra support during the filling process, reducing the need for manual handling by the operator. Direct cost savings for your operational processes.

For our liners, we utilize different types of films. From standard films to EVOH or PET/MET films for specific barriers to ensure maximum product protection.

Curious about how we can assist you? We transform your packaging challenges into innovative solutions, regardless of the container type you use. Feel free to contact us for more information.

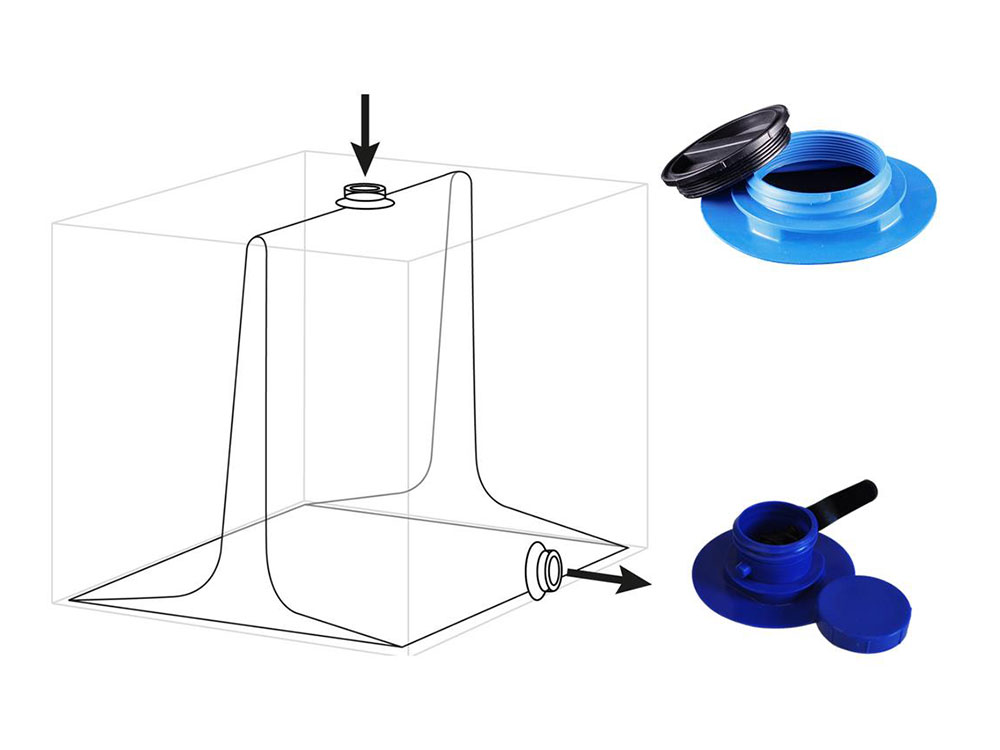

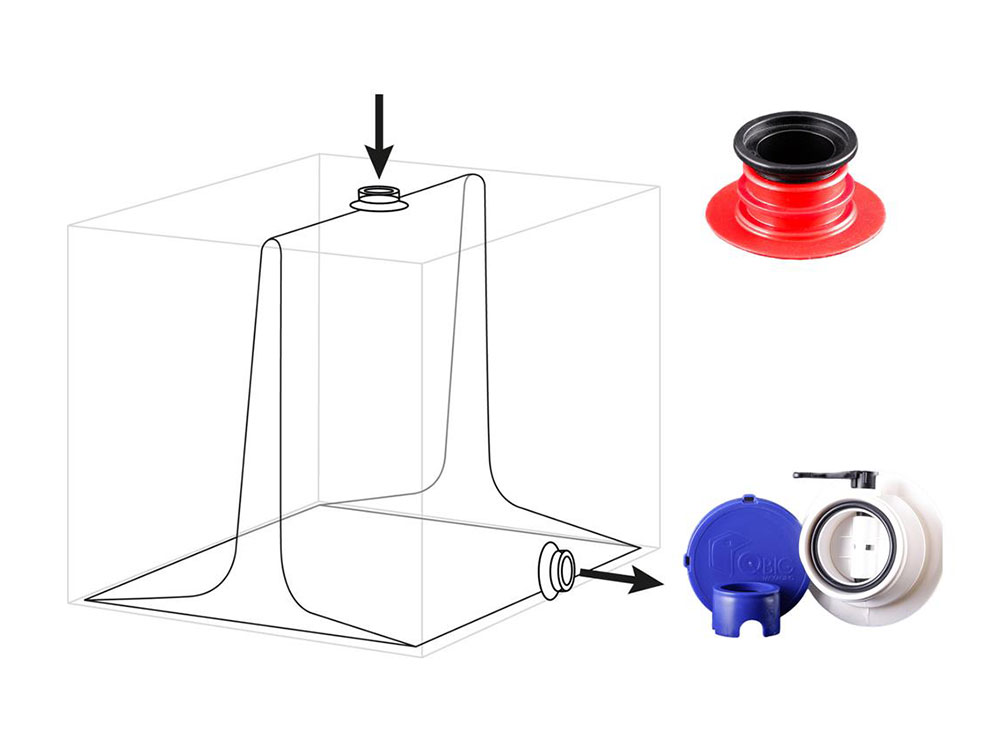

Schutz/Mauser replacement liner

Art no. 410166

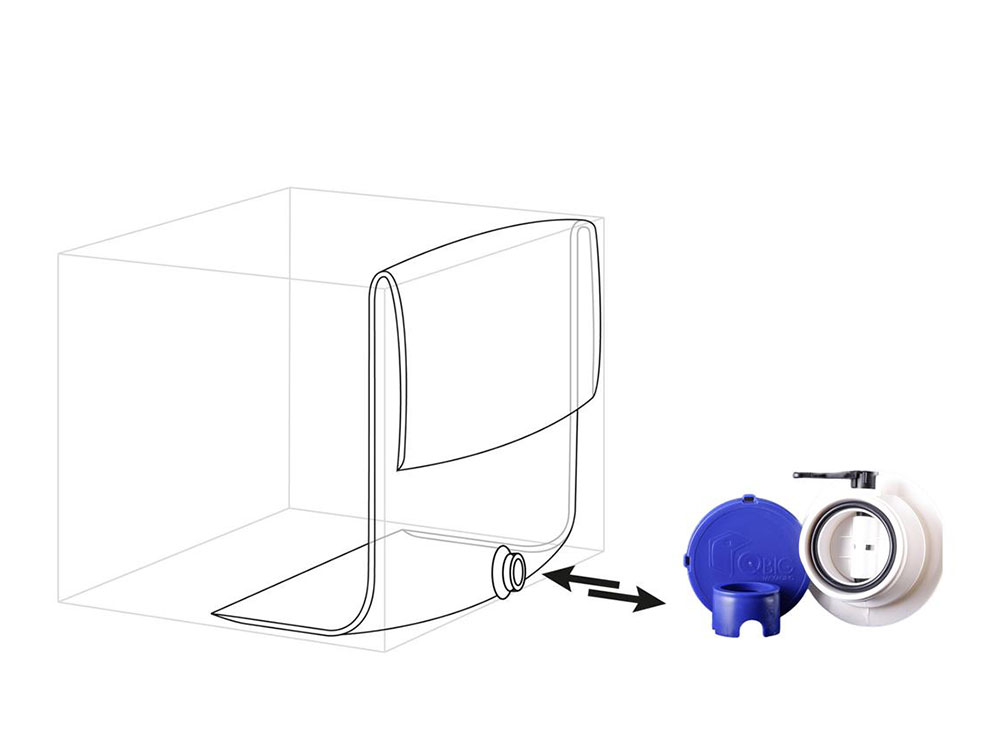

Model: T-liner

Film: 55 µm VLDPE, 55 µm VLDPE, 55 µm VLDPE

Top Fitment: 3” BSP cap

Bottom Fitment: 2” S60 valve

Main industries

Chemicals, rigid IBC replacement

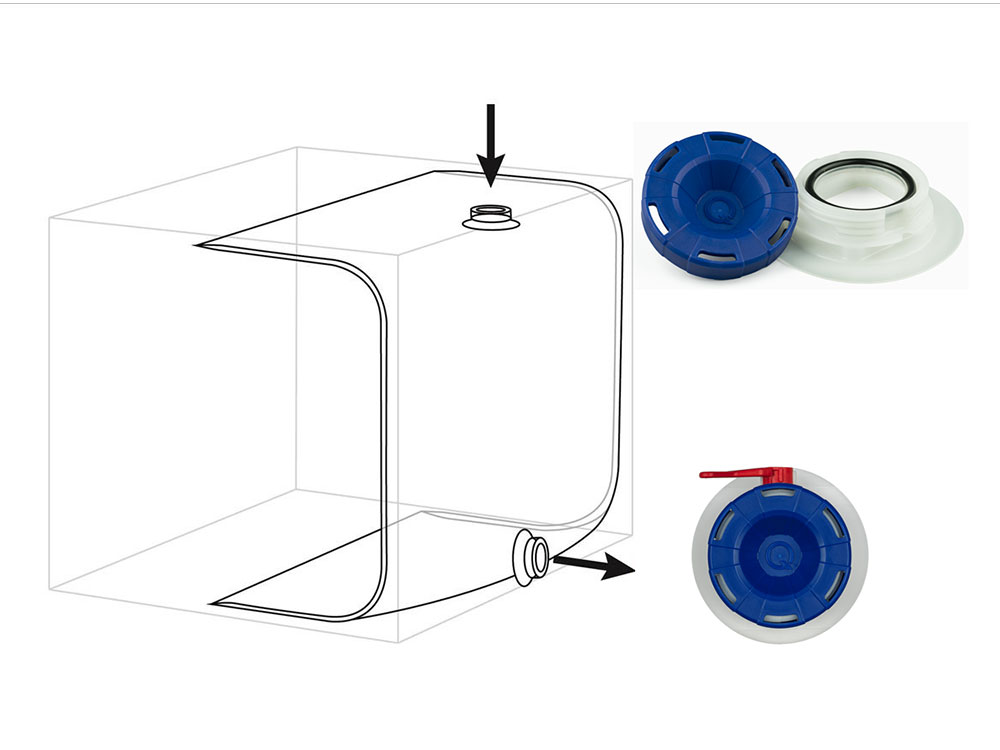

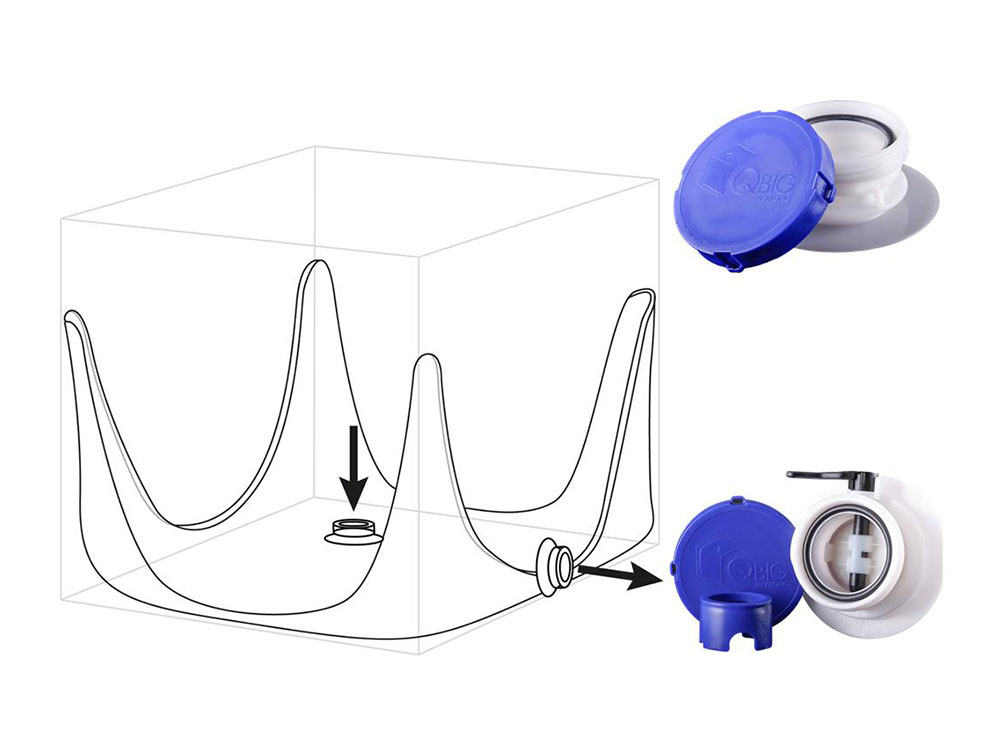

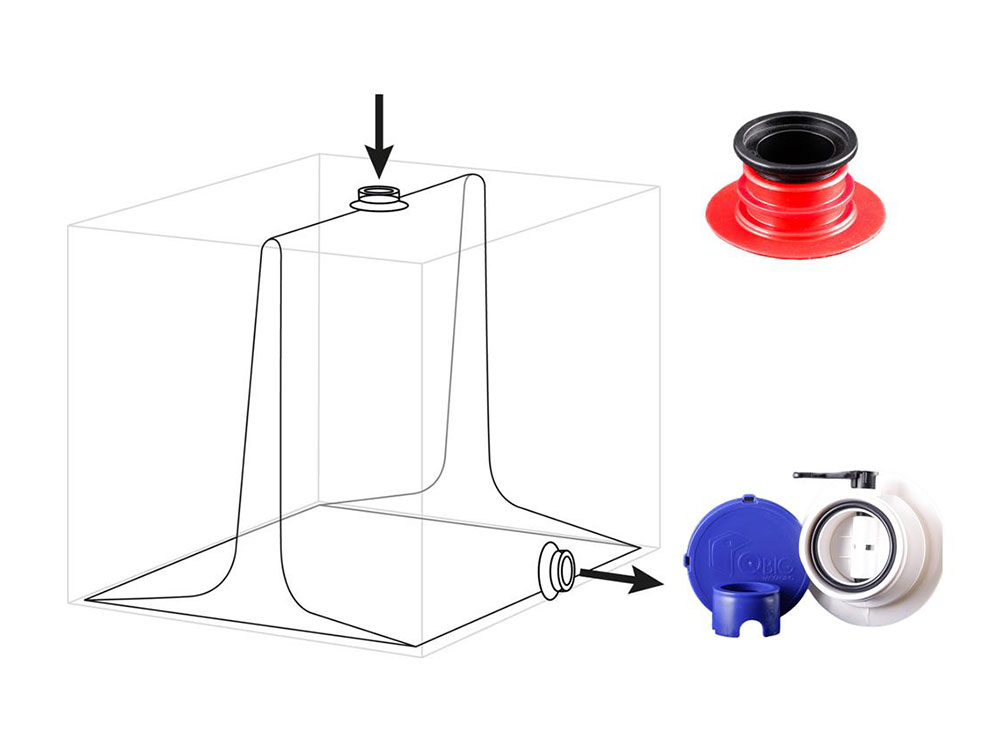

VLDPE FFG liner for food products

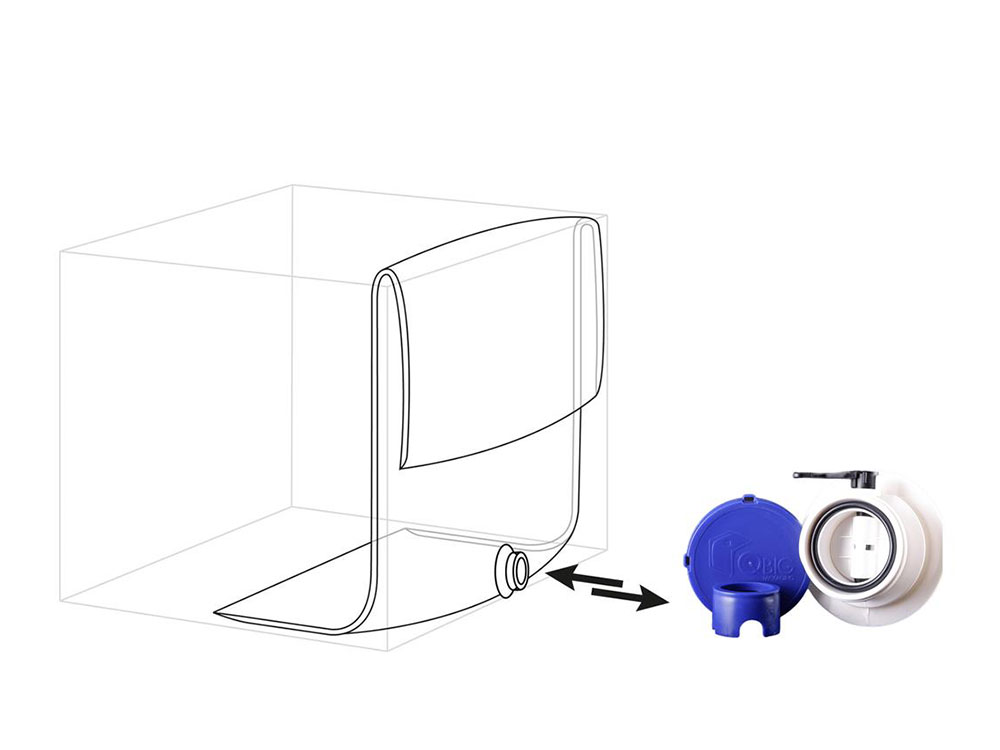

Art no. 410016

Model: Free Flow Gusset

Film: 55 µm VLDPE, 55 µm VLDPE, 55 µm VLDPE

Top Fitment: 2” DN50 filling cap

Bottom Fitment: 2” LP valve

Footprint container: 100×100 cm

Main industries

Food ingredients

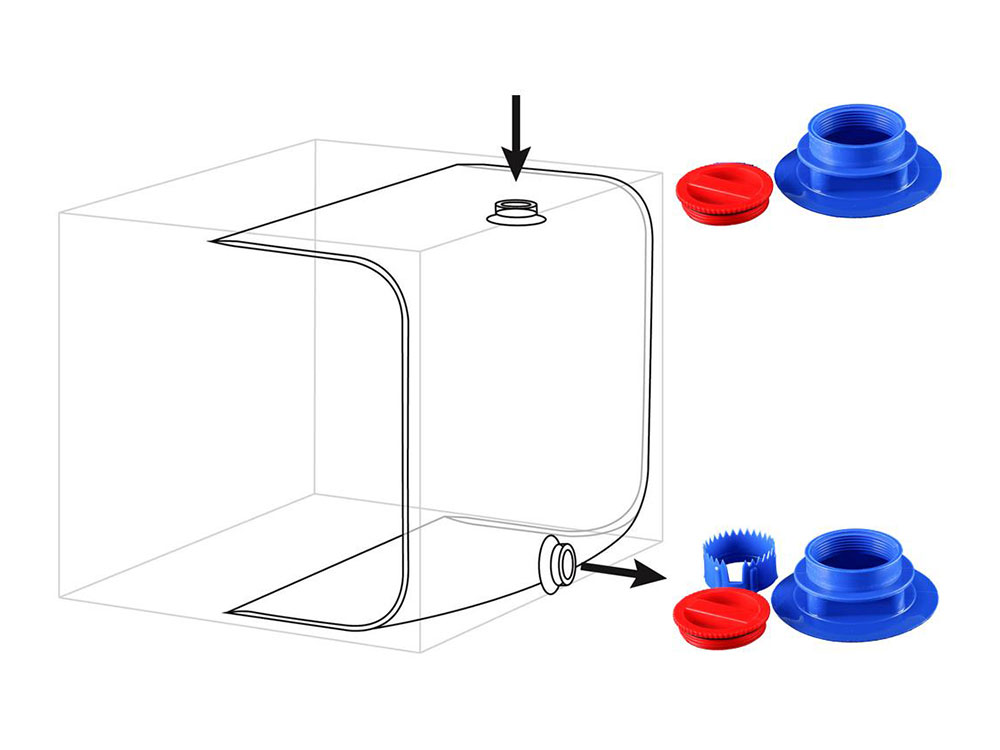

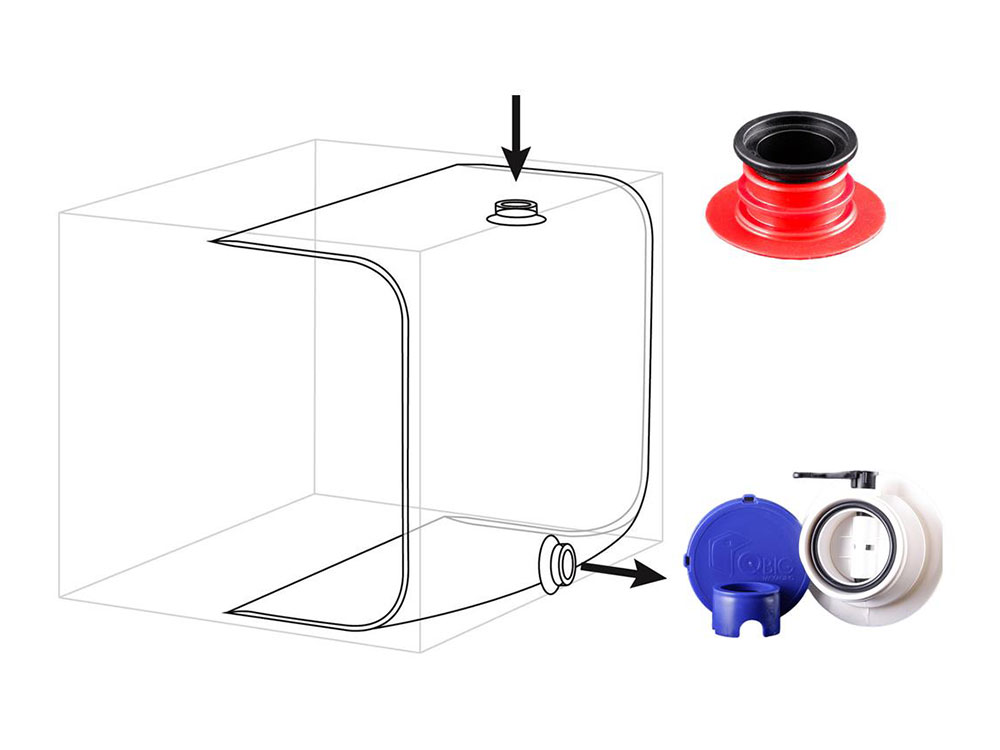

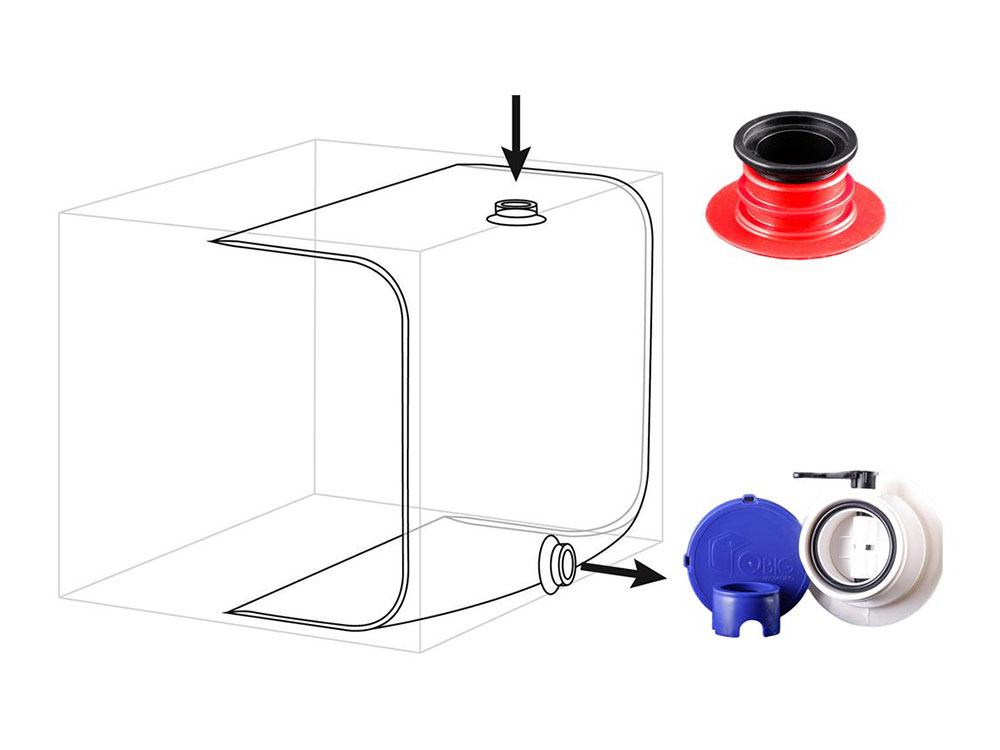

VLDPE FFG liner with conventional fitments

Art no. 410256

Model: Free flow Gusset

Film: 55 µm VLDPE, 55 µm VLDPE, 55 µm VLDPE

Top Fitment: 2” BSP cap

Bottom Fitment: 2” BSP cuttable membrane

Main industries

Various

VLDPE Pillow liner for food products

Art no. 410226

Model: Pillow liner

Film: 55 µm VLDPE, 55 µm VLDPE, 55 µm VLDPE

Top Fitment: 2” DN50 cap

Bottom Fitment: 2” LP valve

Main industries

Food ingredients, liquid egg

VLDPE Pillow liner for food products

Art no. 410226

Model: Pillow liner

Film: 55 µm VLDPE, 55 µm VLDPE, 55 µm VLDPE

Top Fitment: 2” DN50 cap

Bottom Fitment: 2” LP valve

Main industries

Food ingredients, liquid egg

LDPE QUBE liner for high viscous products

Art no. 410126

Model: Qube liner

Film: 120 μm LLDPE, 120 μm LLDPE

Top Fitment: 3” BSP cap

Bottom Fitment: 6” PE Valve

Main industries

High viscous, high value products. (ink, cosmetics)

Heavy duty LDPE T-liner for food products

Art no. 410156

Model: T-liner

Film: 80 µm LLDPE, 80 µm LLDPE, 80 µm LLDPE

Top Fitment: 2” DN50 cap

Bottom Fitment: 2” PE valve

Main industries

Heavy duty food ingredients

EVOH FFG liner to replace kegs-on-legs

Art no. 410206

Model: Free Flow Gusset

Film: 55 µm LLDPE, 55 µm LLDPE, 72 µm EVOH

Top Fitment: none

Bottom Fitment: 2” High Flow valve

Main industries

Dairy, fruit juices and purees

PET-MET FFG liner to replace kegs-on-legs

Art no. 410046

Model: Free Flow Gusset

Film: 55 µm LLDPE, 55 µm LLDPE, 110 µm PET-MET

Top Fitment: none

Bottom Fitment: 2” High Flow valve

Main industries

Fruit juices and purees

EVOH FFG liner for fruit juices

Art no. 410196

Model: Free Flow Gusset

Film: 55 µm LLDPE, 55 µm LLDPE, 72 µm EVOH

Top Fitment: 1” Elpo spout

Bottom Fitment: 2” High Flow valve

Main industries

Dairy, fruit juices and purees

PET-MET FFG liner for fruit juices

Art no. 410216

Model: Free Flow Gusset

Film: 55 µm VLDPE, 55 µm VLDPE, 110 µm PET-MET

Top Fitment: 1” Elpo spout

Bottom Fitment: 2” High Flow valve

Main industries

Fruit juices and purees

EVOH T-liner for fruit juices

Art no. 410236

Model: T-liner

Film: 55 µm VLDPE, 55 µm VLDPE, 72 µm EVOH

Top Fitment: 1” Elpo spout

Bottom Fitment: 2” High Flow valve

Main industries

Dairy, fruit juices and purees

PET-MET T-liner for fruit juices

Art no. 410246

Model: T-liner

Film: 55 µm VLDPE, 55 µm VLDPE, 110 µm PET-MET

Top Fitment: 1” Elpo spout

Bottom Fitment: 2” High Flow valve

Main industries

Dairy, fruit juices and purees

Our liners

Which liner is most suitable?

The type of liner you require depends on various factors, including the product you're filling, the container you use, the filling method, and your customer's expectations. We assist you in finding the best liner and fittings. Below, you can find some practical information on fitments, folding methods, and material.In addition to the standard pillow liner, we also offer the T-liner and Free Flow Gusset (FFG) liner we developed ourselves. These high-quality liners provide extra support during the filling process, reducing the need for manual handling by the operator. Direct cost savings for your operational processes.

Folding methods

Our liners have different folding methods:

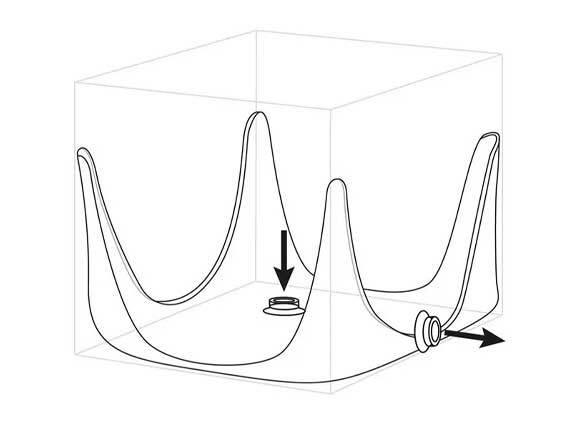

Pillow liner

The Pillow liner has a standard folding method. This liner requires support during the filling process.

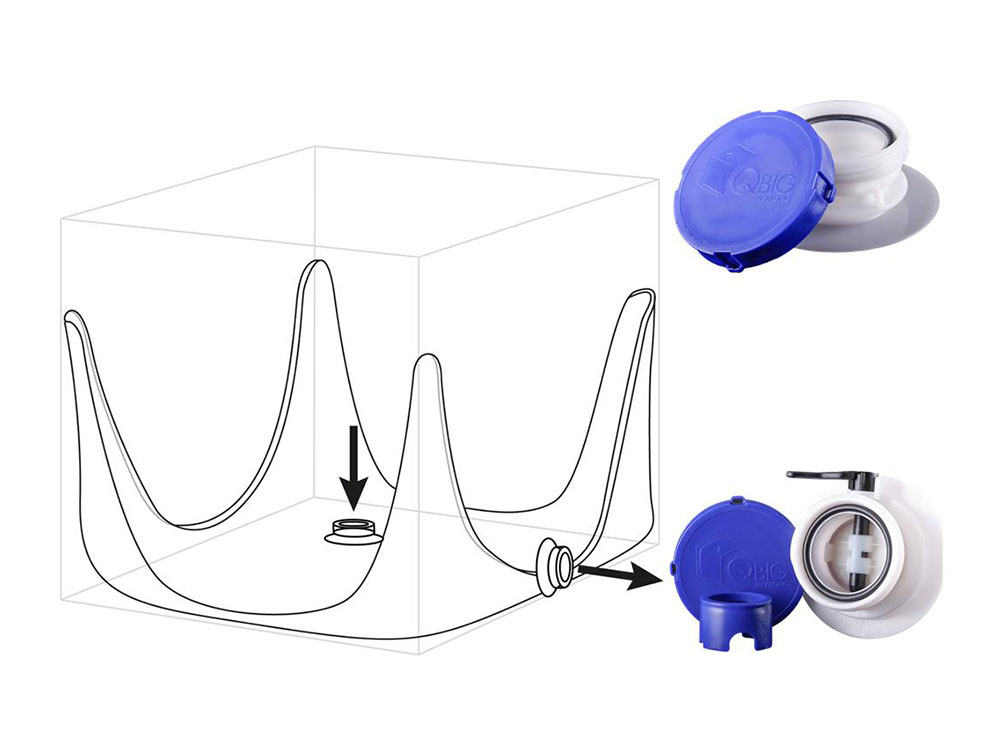

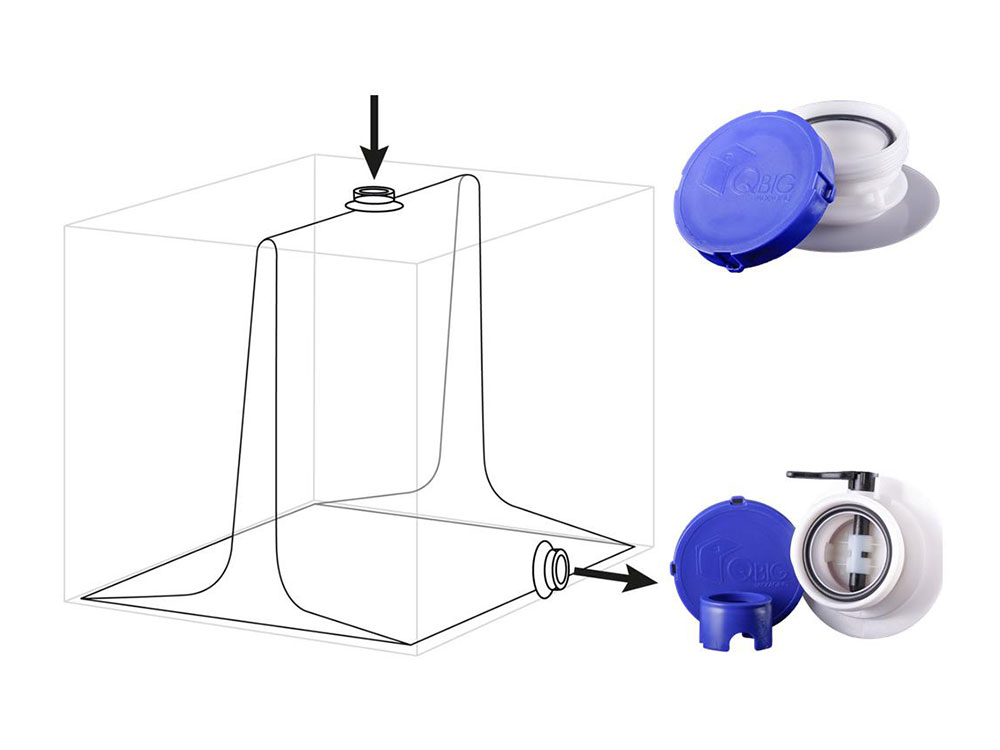

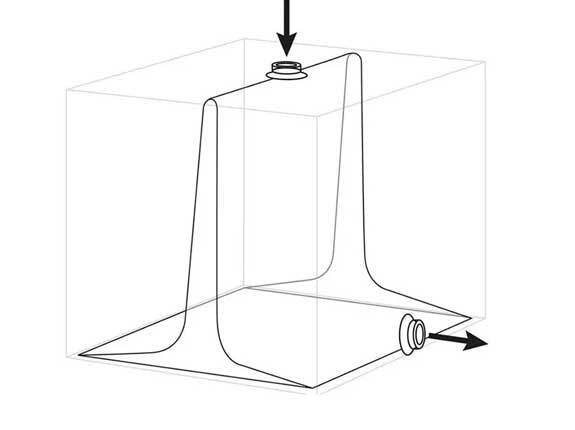

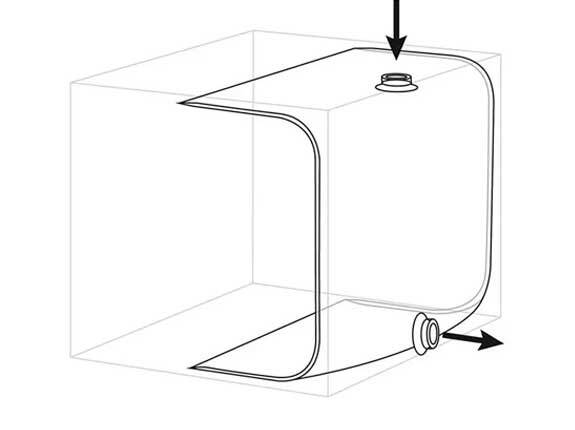

T-liner

The T-liner has a patented folding pattern that doesn't need manual handling during the filling process. A significant advantage of the T-liner is central top filling. Many machines use central top filling. If you prefer a non-central top fill, then the FFG liner is a better choice.

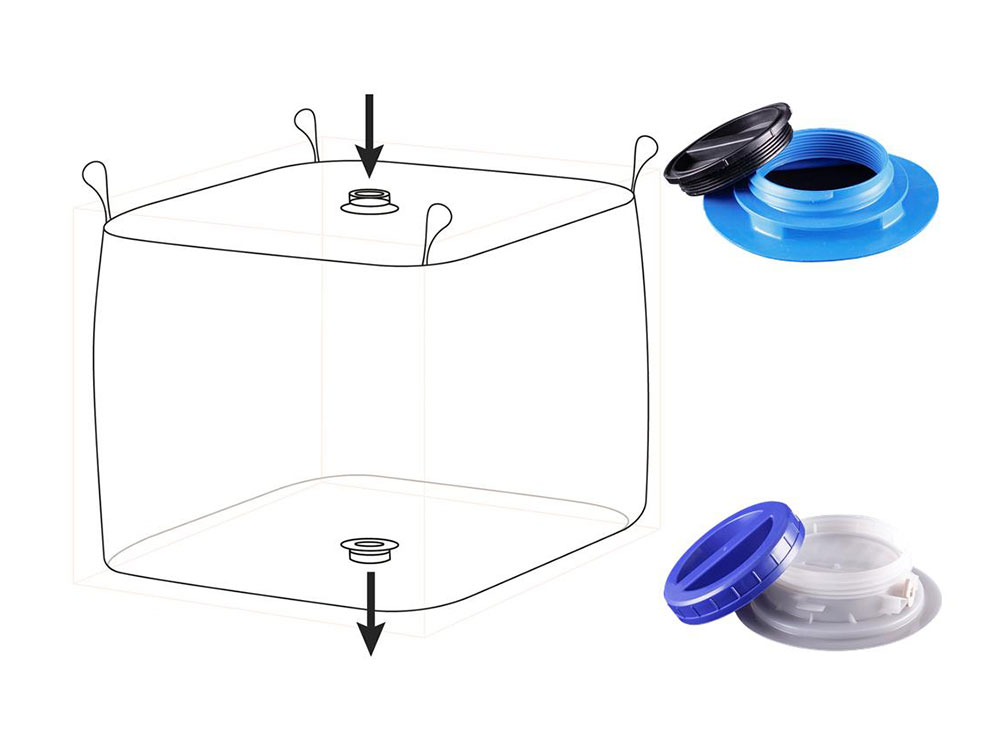

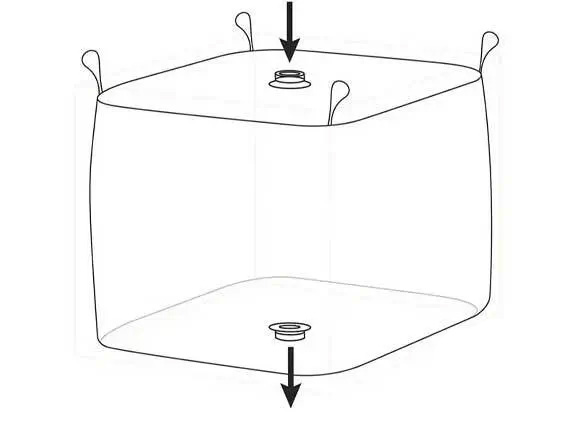

Free Flow Gusset (FFG)

The FFG liner has a patented folding pattern that doesn't need manual handling during the filling process.

This liner is ideal for bottom filling.

Qube liner

The Qube liner is commonly used in conjunction with high-viscosity liquids.

Material

We use 3 different materials. In the food industry, as well as in other sectors, a 3-layer VLDPE material is the standard. Need an oxygen barrier? We recommend an EVOH film. If a UV barrier is also desired, opt for a metallized PET/MET material.

Fitments