Straight to:

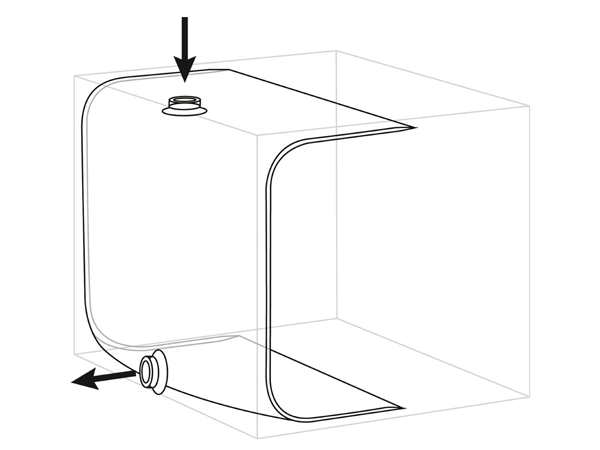

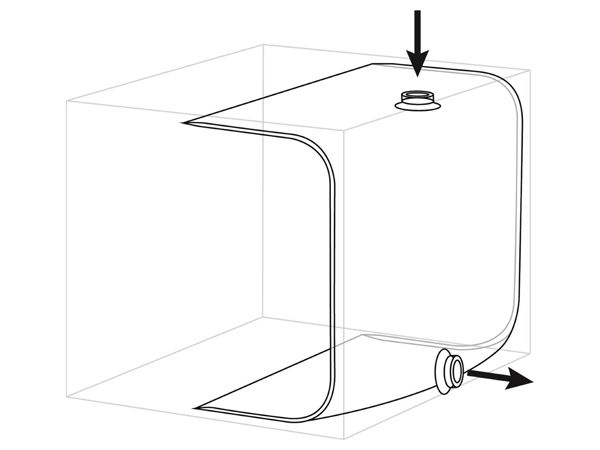

Qbig understands that the way an IBC liner is folded can make a significant difference in handling, filling efficiency, and overall product performance. That’s why we apply several carefully engineered folding methods, each designed to minimize the residual product, reduce operator time, and ensure a smooth filling and discharge process.

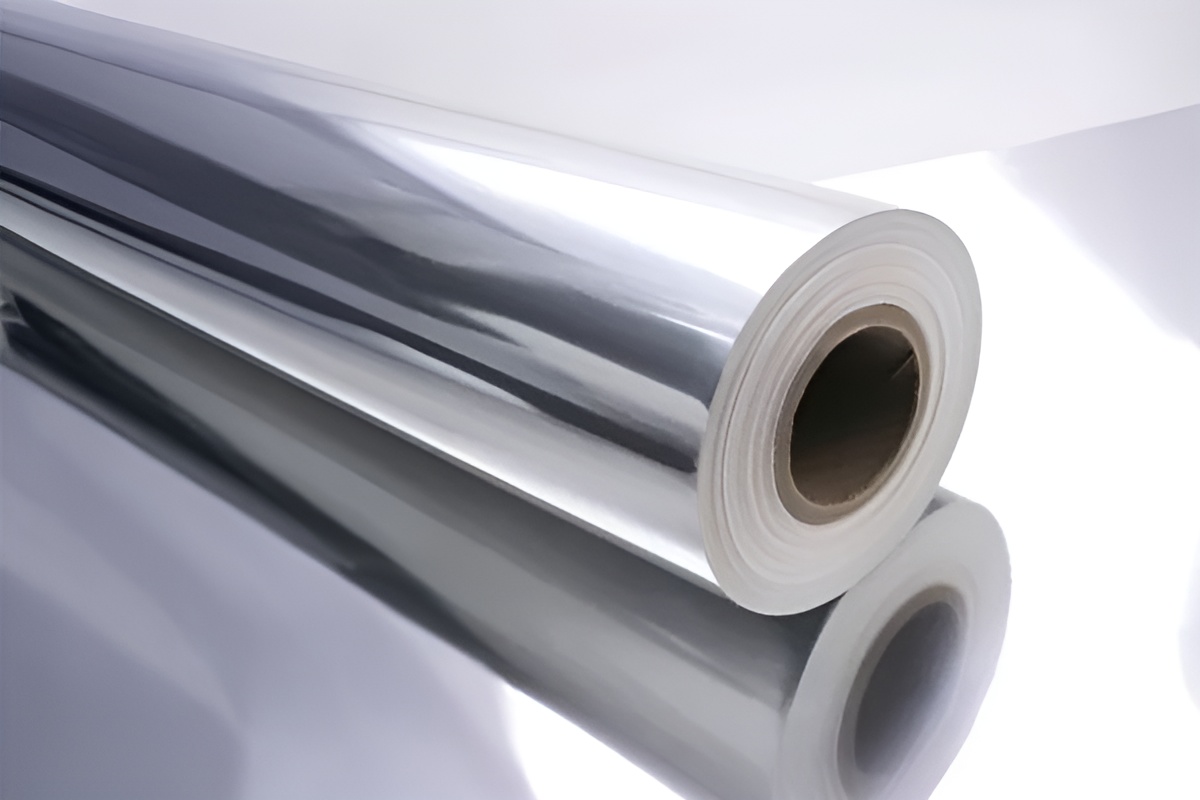

The industry standard film, widely used across the globe for its reliability and versatility in a broad range of liquid applications.

A high-performance film featuring an excellent oxygen barrier, ideal for products sensitive to oxidation and requiring extended shelf life.

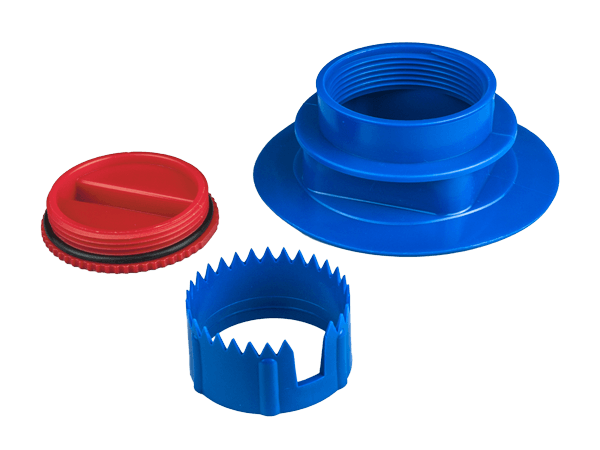

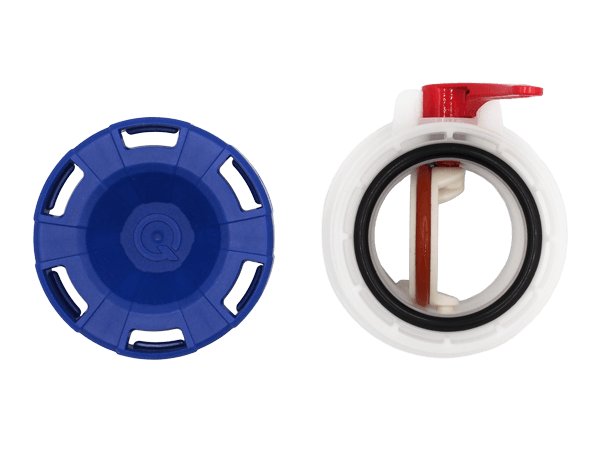

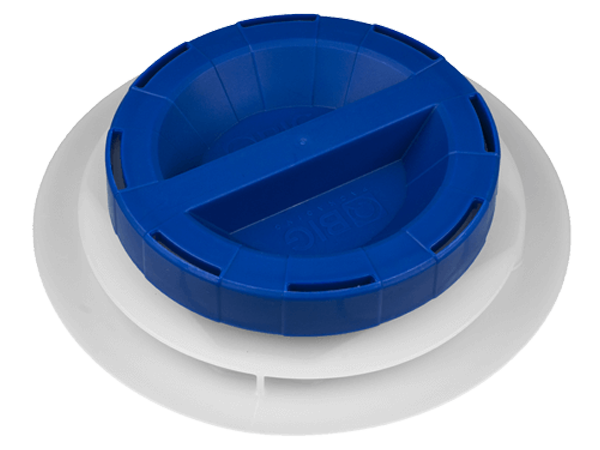

All liners are fully integrated with the Qflow fitment range – including valves, filling caps, and fixation clips – ensuring a seamless process from filling to discharge. Manufactured in Europe, each valve is leak-tight tested in a ISO 7 cleanroom production, developed with a strong commitment to social corporate responsibility.

We offer a wide range of filling caps from 1″ to 6″ for filling liquids into IBC liner bags. In addition to this standard selection, we can produce any custom filling cap to meet your specific requirements.

Get in touch with our team to find the best liner setup for your packaging needs. We’re happy to advise based on your process, product, and performance goals.