Straight to:

Challenges

Requirement: Aseptic filling

Qbig solutions:

Product examples

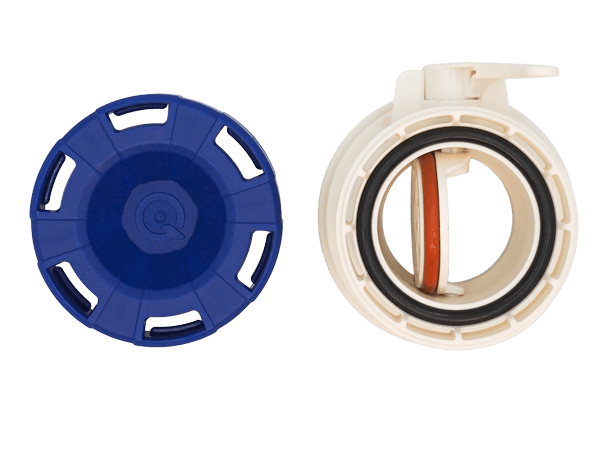

With over 20 years of experience, Qbig delivers proven solutions for aseptic packaging. Our patented CST valve has earned global trust thanks to its simplicity, reliability, and economic advantage. The steamable valve material is ideal for irradiation, ensuring maximum safety and compliance. Combined with our expertise and innovative design, Qbig offers a complete solution for the processed fruit sector’s stringent requirements.

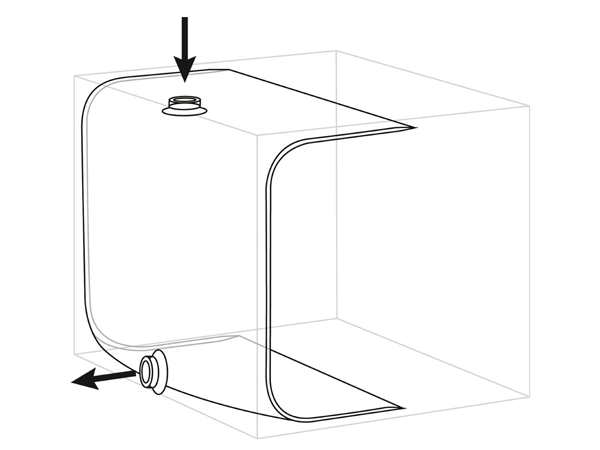

With our Free Flow Gusset technology, operators can connect the valve to the filling line, and start filling, without the needs to manipulate the liner. As they also do with their kegs on legs. Our barrier films make sure the product is preserved in the right way, and under the right circumstances. It fully meets the industry standards for fruit juices and concentrate. For (mainly) the US market, fitments equipped with ‘Tri-Clover’ connections are available.