Qbig Packaging

Fitments

for liquids

Qbig has created a wide portfolio of fitments used in the liquid bulk packaging industry. These fitments are available for and used by liner and big-bag manufacturers world-wide.

Step into the innovative world of Qbig's fitment solutions for the FIBC industry.

Fitments

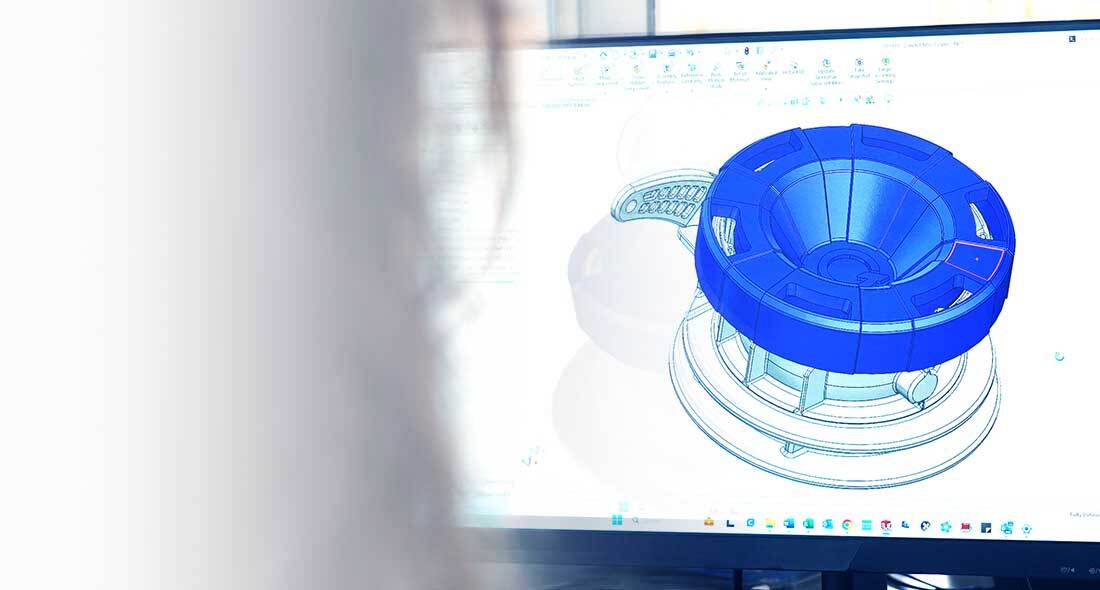

Step into the innovative world of Qbig's fitment solutions for the FIBC industry. We provide solutions to optimally fill, package, and transport your products. This includes taps/valves, filling caps, and accessories for filling and emptying low to highly viscous liquids.

With an extensive range and years of experience in the development and production of high-quality valves, we are experts in this field. We developed a wide portfolio of fitments for use in the liquid bulk packaging industry.

Top-fitments or filling caps range from 1” to 6”, and for valves, this varies from 2” to 8”. For aseptic processes, for instance, we offer steamable valves, but of course, we also provide non-steamable versions.

All our products are BPA-free and are designed not just for optimal performance but also for optimal design, allowing us to use less plastic in production. Over the past 2 years, we have been able to save over 25% through smarter engineering of our fitments.

At Qbig, we share the common goal of reducing waste throughout the supply chain. With our filters, applied to the contents of FIBCs, you can create MAP packaging that significantly extends the shelf life of your products by protecting them from external influences. Discover how our fitments can optimize your packaging process and contribute to a more sustainable future.

Filling cap with venting solution. Prevents for pressure build-up. Open gas flow with outside.

Filling cap with venting solution. Prevents for pressure build-up. Open gas flow with outside.Types

CapsMain industries

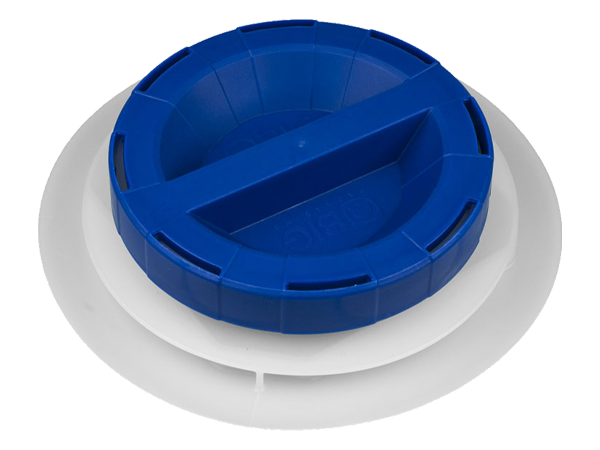

Liquids containing gas2″ DN50 degassing cap

5007.10042″ DN50 filling cap

5007.1003 Robust two component valve for filling and/or multiple cycle discharge operations. Strong material for the best connection with pumps and piping. Suitable for hot-fill operation and application.

Robust two component valve for filling and/or multiple cycle discharge operations. Strong material for the best connection with pumps and piping. Suitable for hot-fill operation and application.Types

ValvesMain industries

Cosmetics2″ DN50 Q2 Valve

5014.4000 Viton-seal solution when silicone seals cannot be used. Strong material for the best connection with pumps and piping. Suitable for hot-fill operation and application.

Viton-seal solution when silicone seals cannot be used. Strong material for the best connection with pumps and piping. Suitable for hot-fill operation and application.Types

ValvesMain industries

Cosmetics2″ DN50 Valve- Viton

5004.2001 Efficient valve for filling and/or discharge operations. Direct weld on liner, no loose handles. Application up till 40 C.

Efficient valve for filling and/or discharge operations. Direct weld on liner, no loose handles. Application up till 40 C.Types

ValvesMain industries

Cosmetics2″ DN50-E Valve

5014.5000 Robust two component valve best suited for irradiation and steam-sterilization. Strong material for the best connection with pumps and piping. Suitable for hot-fill operation and application.

Robust two component valve best suited for irradiation and steam-sterilization. Strong material for the best connection with pumps and piping. Suitable for hot-fill operation and application.Types

ValvesMain industries

Cosmetics2″ DN50-S Valve

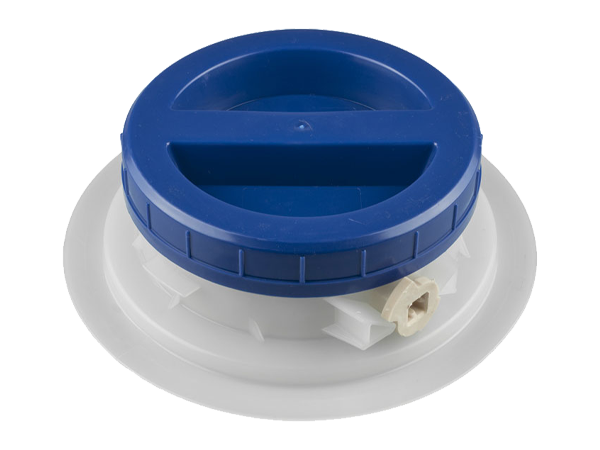

5014.3000 Base fitment to click-fit DN50 valves in liners. This counterpart is to be welded on liners. Soft LDPE material with easy welding properties.

Base fitment to click-fit DN50 valves in liners. This counterpart is to be welded on liners. Soft LDPE material with easy welding properties.Types

Auxiliaries2″ Press-Fit Valve Base

5005.2000 Bottom discharge valve when every drip counts. To be applied in existing bottom discharge containers.

Bottom discharge valve when every drip counts. To be applied in existing bottom discharge containers.Types

ValvesMain industries

High viscous2″ S60 Sump Valve

5004.4000 Base fitment to click-fit DN50 valves in liners. This counterpart is to be welded on liners. Soft LDPE material with easy welding properties.

Base fitment to click-fit DN50 valves in liners. This counterpart is to be welded on liners. Soft LDPE material with easy welding properties.Types

Auxiliaries2″ Valve Base

5005.10013″ DN75 filling cap

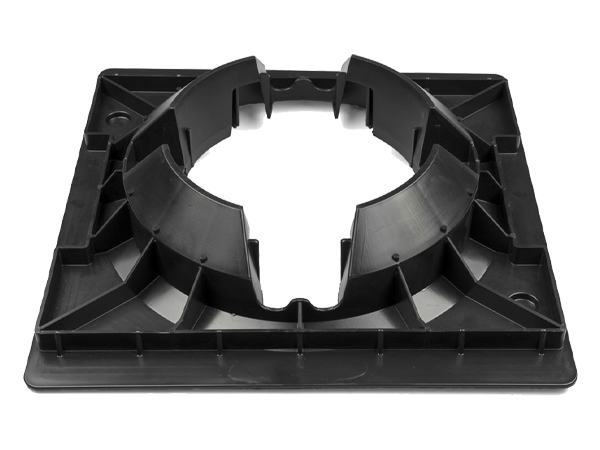

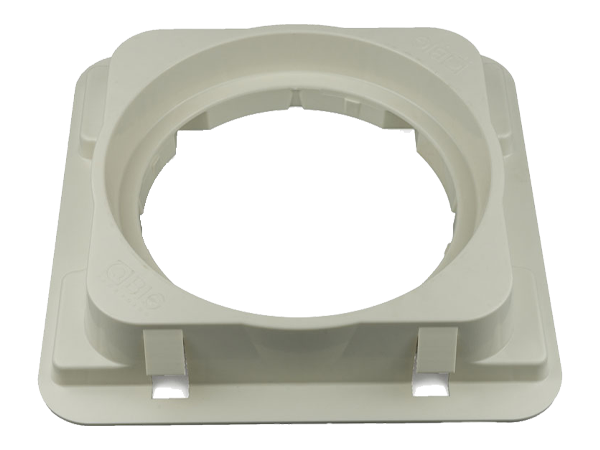

5030.10026″ Base plate

5060.10026″ filling cap

5060.1000 Allows to vacuum and seal vacuum bigbags. Especially interesting in Modified Atmosphere Packaging (MAP).

Allows to vacuum and seal vacuum bigbags. Especially interesting in Modified Atmosphere Packaging (MAP).Types

ValvesAir Release valve

6000.1000 Controlled atmosphere technology fitment. Unique Modified Atmosphere Packaging (MAP) fitment. Effectively create and maintain a controlled atmosphere in bigbags. Protecting both powder and pump by unique filter applied.

Controlled atmosphere technology fitment. Unique Modified Atmosphere Packaging (MAP) fitment. Effectively create and maintain a controlled atmosphere in bigbags. Protecting both powder and pump by unique filter applied.Types

ValvesCAT-88 VALVE

6000.1105CP8 Base plate

5080.1001CP8 membrane

5080.1000 Base fitment to click-fit DN50 valves in liners. This counterpart is to be welded on liners. Soft LDPE material with easy welding properties.

Base fitment to click-fit DN50 valves in liners. This counterpart is to be welded on liners. Soft LDPE material with easy welding properties.Types

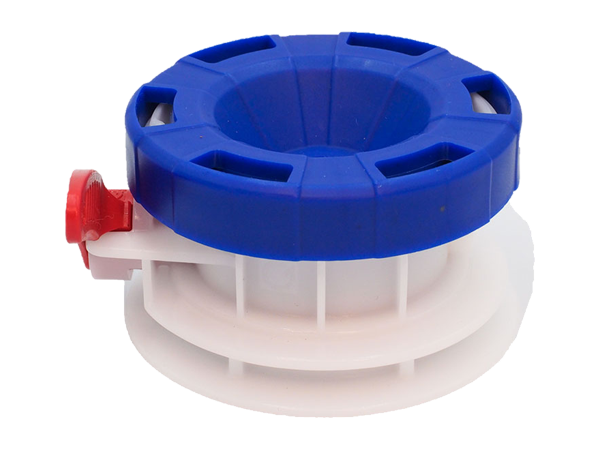

AuxiliariesDouble3 Base

5025.1000 Robust two component valve for filling and/or multiple cycle discharge operations. Strong material for the best connection with pumps and piping. Especially suitable for high viscous liquid or product with particles.

Robust two component valve for filling and/or multiple cycle discharge operations. Strong material for the best connection with pumps and piping. Especially suitable for high viscous liquid or product with particles.Types

ValvesMain industries

CosmeticsDouble3 Valve

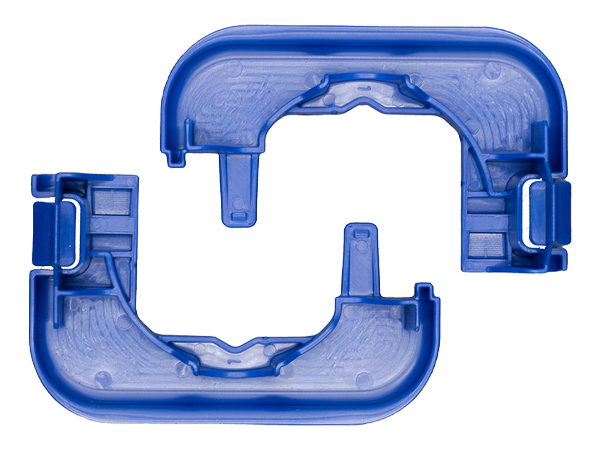

5020.1000 Alternative clip to click fit Qbig side-discharge valves where the standard does not fit. Fit with Onetrip XXL, Cargocube of customer specific. Ask for advice.

Alternative clip to click fit Qbig side-discharge valves where the standard does not fit. Fit with Onetrip XXL, Cargocube of customer specific. Ask for advice.Types

ClipsFix clip 160

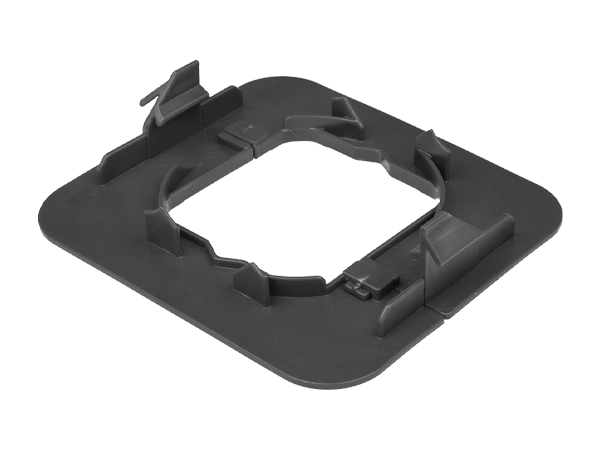

5060.1050 Clip to click fit any Qbig side-discharge valve in conventional (plastic) foldable containers. Perfect fit with Pallecon, CL285, Excelsior, Superior, Iconic and many others.

Clip to click fit any Qbig side-discharge valve in conventional (plastic) foldable containers. Perfect fit with Pallecon, CL285, Excelsior, Superior, Iconic and many others.Types

ClipsFix clip Blue

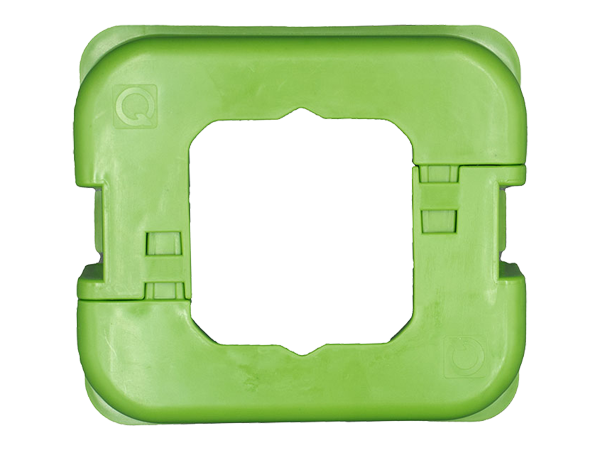

5060.4000 Alternative clip to click fit Qbig side-discharge valves where the standard does not fit. Fit with CL65, certain cardboard containers. Ask for advice.

Alternative clip to click fit Qbig side-discharge valves where the standard does not fit. Fit with CL65, certain cardboard containers. Ask for advice.Types

ClipsFix Clip Green – 2020

5003.1004 Alternative clip to click fit Qbig side-discharge valves where the standard does not fit. Fit with Goodpack, most metal containers, some carboard options. Ask for advice.

Alternative clip to click fit Qbig side-discharge valves where the standard does not fit. Fit with Goodpack, most metal containers, some carboard options. Ask for advice.Types

ClipsFix clip Grey

5003.1000 Wire-seal to secure closed valves or filling caps after filling. Market standard to prevent for food fraud. Works with all 2 inch and 3 inch valves and caps.

Wire-seal to secure closed valves or filling caps after filling. Market standard to prevent for food fraud. Works with all 2 inch and 3 inch valves and caps.Types

AuxiliariesTamper Evident

5045.1000

Modified Atmosphere Packaging

The right atmosphere with Modified Atmosphere Packaging (MAP) methods

When packaging a product, retaining its color, shape, and freshness is crucial. For an optimal environment, you would choose Modified Atmosphere Packaging (MAP). As the name implies, the natural atmosphere is replaced by a protective one, specifically tailored to the product, without the use of extra chemicals. Often, a protective atmosphere contains substances like carbon dioxide, nitrogen, or oxygen.

At Qbig, our focus is on developing filter solutions for packaging materials to maintain this special atmosphere. This ensures that the protective atmosphere remains intact without leaks, preventing the intrusion of oxygen, moisture, or undesired substances. By adding one of our specially designed fitments for the MAP method to your packaging, you can maintain the desired atmosphere.

Discover how our filter technology for MAP applications contributes to longer shelf life, improved product safety, reduced food wastage, and enhanced transport protection.

Liner solutions