Qbig Packaging

Co-development

Fitments that match the contents of the liner and also meet your requirements might seem like a daunting task, perhaps even custom-made.

High-quality materials

Co-development

Fitments that match the contents of the liner and also meet your requirements might seem like a daunting task, perhaps even custom-made. Know that we are keen to leverage our knowledge and experience to collaboratively develop and implement new customer-specific packaging products or concepts with you. All tailored to your unique requirements for packing both liquid and solid substances. And even suitable for Modified Atmosphere Packaging (MAP) methods.

What sets us apart as a partner is our ability to realize products in a relatively short time frame. Thanks to our in-house R&D team, patented designs, and modern, certified production facilities, we operate quickly and efficiently. Below you can already view some interesting customer cases.

Our taps, filling caps, and other accessories are made from high-quality materials, FDA approved of course, and are suitable for various applications, including hot-fill and aseptic applications for industries like cosmetics, food, or ink. Flawless performance is key, as every drop or gram counts! Our product developments are focusing on bringing you the right product that saves money due to its efficiency whether it be in the fitment itself or it’s operational usage.

Co-development

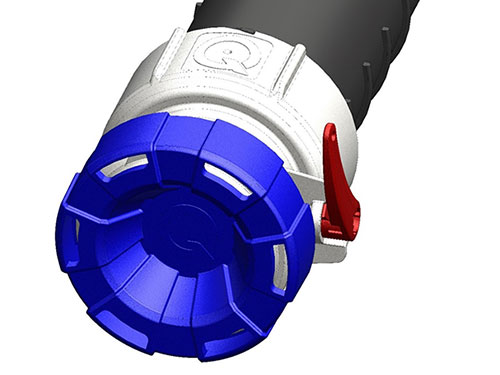

S100x8 Valve

For a packaging manufacturer active in high viscous products such as in the mining industry we have developed a unique 3 inch valve. The valve is developed making use of our patented and proven CST-technology, also applied in our DN50-S valve. Making smart combinations and listening to customer input has led to a unique valve that could seamlessly be added to the customer’s portfolio. And not just as portfolio filling; but as a flagship of their solution.

Co-development

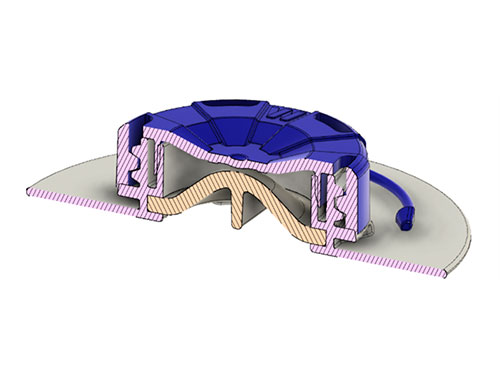

CAT-40 Valve

In Modified Athmospere Packaging (MAP), we have developed the CAT-40 valve. Using this tiny fitment in a bag of seeds, tobacco, nuts etc. can be extremely value adding. The CAT-technology within this product allows to release the oxygen, replace by nitrogen or carbon-dioxide and therewith extend the shelflife of the packaged product.

Co-development

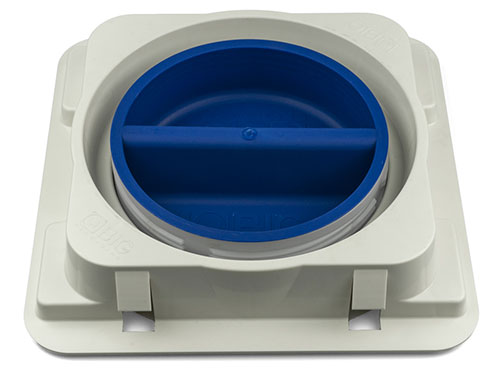

CP8 membrane and baseplate

A glucose trader developed a brand new concept to pack, transport, re-liquify and re-pack glucose. In this project a steer-and-heat machine was build to liquify glucose from it’s packaging. The steer and heat machine entered the packaging from the bottom, through an 8 inch hole and in this way made sure that the high-viscous glucose could optimally be discharged. The connecting fitment to be used on the packaging however was not yet designed. Qbig developed the concept, used well-known cuttable membrane technology in combination with it’s knowledge on 6 inch valve baseplates and realized a product that was the missing link in the packaging and machine connection.